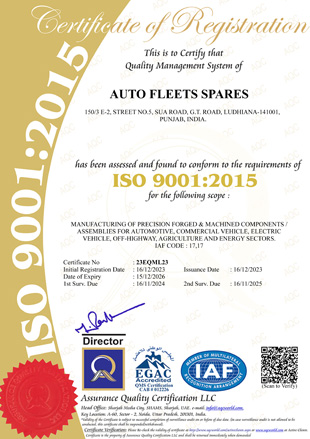

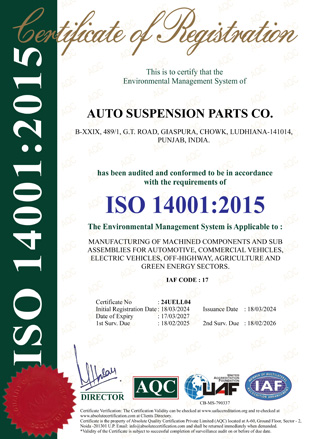

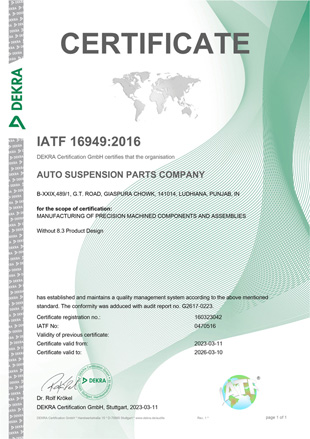

Quality Assurance

Quality

Quality

ASCO is unique manufacturing company operating with quality concious clients within the Heavy Duty, Automotive, Agro, Off-Highway & Energy sectors.

We aim to be the most professional and reliable supplier partner in our industry, with total commitment to safety, quality and operational excellence.

Our reputation is our greatest asset. It is founded in oue values and embodied on our Code of Conduct.

Our goal is to exceed customer expectations for quality, to deliver reliable and defect free products.

We incorporate below mentioned fundamentals in our manufacturing practices.

- APQP

- POKA YOKE

- SPC

- Continious Improvement

- 5S

- Quality Circles

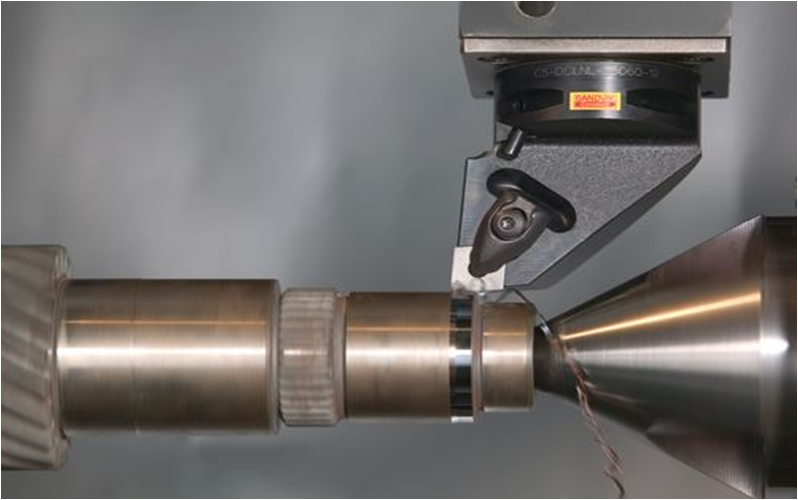

Supperior Tooling

We do not believe in short-cuts. Need consistent quality product? We rely only on OEM tooling with proven track record, to take the gueswork out of precision and repeatability.

Design Capabilities

“Quality is inbuit in your manufacturing process”

Production process planning and developing stage-wise control plan is the backbone of our manufacturing culture.

NPD, reverse engineering, GD&T is all assisted by our design department.

APQP Proactive Quality

“Quality is inbuit in your manufacturing process”

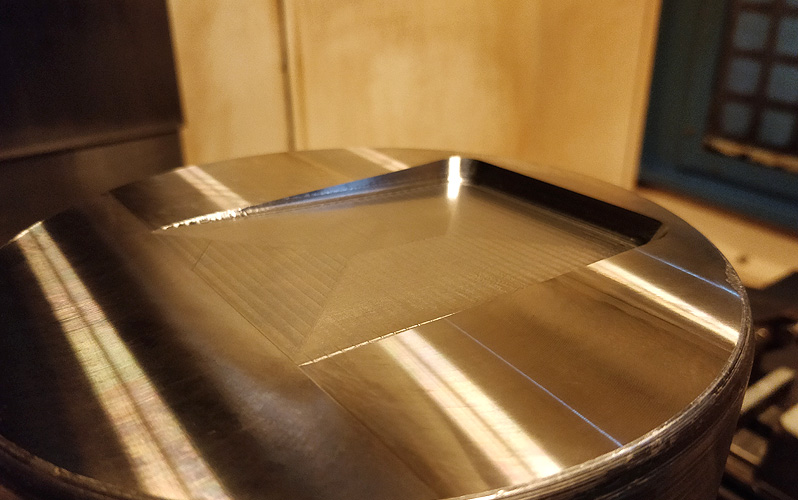

Saving your precious time by very low setup times using integrated CAD/CAM solutions.

Utilizing CAD/CAM software, product specifications are highly controlled from the start.

Tools & Die Design/Manufacture

Careful die-steel selection and specific heat treatments are utilized such as Vacuum HT with extended tempering cycles.

Utilizing CAD/CAM software, product dimensions are highly controlled from the start.

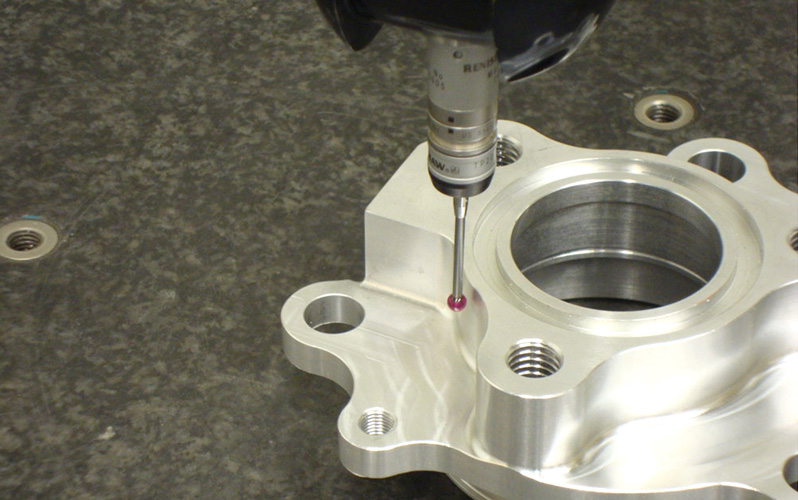

Testing & Homologation

Range of Homologation and Testing facilities are availed for OEM applications from relevent agencies.

- NABL CERTIFIED INSPECTION

TESTING & HOMOLOGATION

3rd PARTY INSPECTION

Trainings and Association Participations