Infrastructure

Infrastructure

Manufacturing Excellence

In depth knowledge and understanding the product parameters before starting production is our basic guiding principle of manufacturing. We aim for 100% first time PPAP lot approval.

You can expect a lot from our expertise in manufacturing precision components which meet international standards and cusomer specifications.

Our team is well equipped to offer you the best.

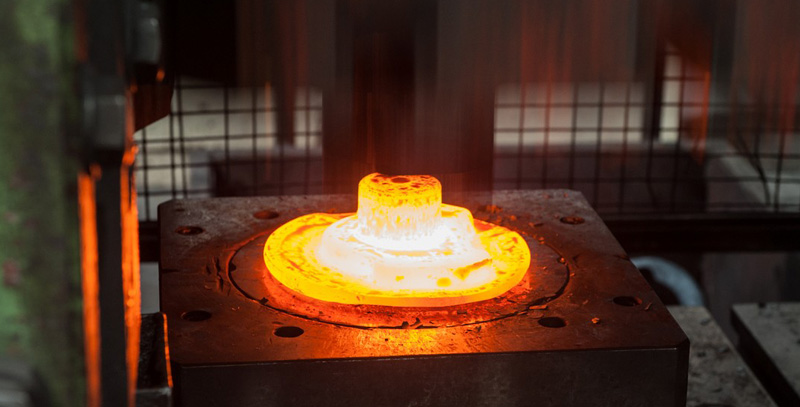

Forging

- Drop Forging

- Press Forging

- Reverse Extrusion

- Ring Rolling

- 0.5kg to 20kg Forgings

Heat Treatment

Supported by qualified Metallurgists.

Expertise in Heat Treating following grades- Carbon Steels, Carburizing Steel, Low Alloy Steel, High Alloy Steels.

- Hardenining, Tempering

- ISO-Thermal Annealing

- Normalising

- Case Carburising

- Nitriding / Sursulf

- Induction Hardening

Shot-Blast & Shot-Peen

Auto-Loading batch shot-blasting machine with efficient throughput and HMI.

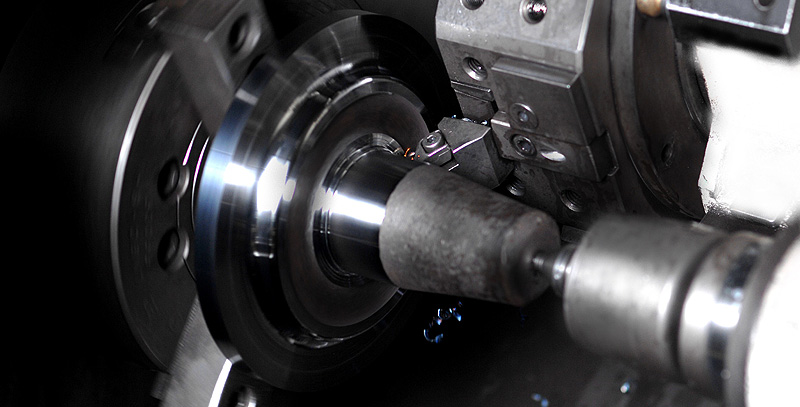

Precision Machining

Offering you the latest manufacturing capabilities with our CNC Turnings, CNC Vertical Millings, CNC Turnmills, Broaching, Deep Drilling and many more.

CNC/VMC makes:

TSUGAMI (JAPAN), LMW, TAL, ACE.

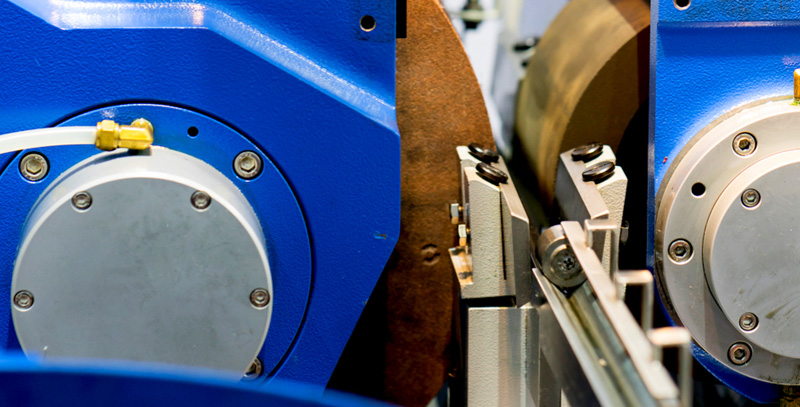

Grinding

For those close tolerance fitting parts, we offer our setup of Centreless grinding and Cylindrical grinding machines

Coating

Range of coatings offered:

E-Coat, Dacromet / Zn-Al Flake coatings, Trivalent Zn Plating, Mn/Zn Phosphating

Priority on Material Handling

Careful material handling is our culture. We ensuring all products reach you spick and span.